(A) FOR EXPORT MARKETS:

1) QUANTITIES are limited.

2) COSTS are not competitive.

3) QUALITY is poor.

4) RELIABLILITY of supply is absent.

(B) FINANCIAL INSTITUTIONS:

1) The financial institutions are in the business of lending depositor’s money at an interest rate to make a profit.

2) They lend to low risk areas.

3) The non-traditional agriculture sub-sector in South American region is high risk because of its disorganization.

4) To attract attention in the financial and insurance sectors, it must re-organize through parks.

(C) AGRICULTURAL LANDS:

For crops to be productive on agricultural lands, certain conditions must exist:

(1) The drainage systems must be vibrant, getting rid of all excess water which is a hindrance to full production and productivity.

(2) The irrigation system must be active. The soil must have certain degree of moisture to successfully assist the crops to maximize their outputs.

(3) The composition of the soil and the crops must be related; they must be balanced for good results.

(D) THE FARMERS:

(1) The farmers have a poor knowledge of their tropical environment, working odd hours with poor returns. Certain agricultural sectors such as rice cultivation have shown the way, working from the early hours in the morning to mid-days.

(2) Farmers generally have a poor knowledge of soil composition; nutrients needed by various crops, the importance of proper drainage and irrigation systems to regulate the moisture content of the soil to assist the crops to draw their food (nutrients). Farmers usually rely on established cultures to determine the amount of fertilizers to apply to fields and crops. No attempts are made to do scientific testing e.g. Soil, water, leaf, or tissue.

(3) Farmers are too often not aware that the genetic makeup of seeds and plants do have a direct bearing on production yields. They most often cultivate poor quality seeds and plants from third and fourth generation crops thereby adding to their poor incomes.

(4) Farmers whether in the rice, fruits, vegetables, fishing etc. have a poor understanding of market forces since most of them operate for a small local market. They have no knowledge that on the world markets, there are big differences between US 10 cents and US 12 cents per kilograms.

(5) Volume; Cost; Quality; reliability and competitiveness of supplies are foreign terms to most.

(E) AGRICULTURAL DEPARTMENTS AND INSTITUITIONS:

All these bodies are under-utilized. They are numerous, staffed with some highly qualified persons who can assist in all agricultural fields to lift the standards to international level by training thousands of farmers.

(1) Four in Peru.

(2) Four in Brazil.

(3) Four in Guyana.

(4) Two in Suriname.

(5) One in French Guiana.

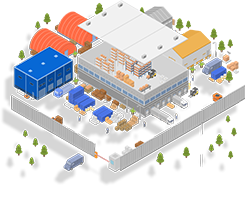

These parks will be managed on a commercial basis.

(A) THE ADMINISTRATIVE BUILDINGS: will be the nuclei to manage these parks,

The Research, Veterinary and Quality Control Centres will provide technical services.

Qualified staff with I.T. network and air conditioned buildings.

From these management centres, all the parks will be developed.

(B) PESTICIDES AND WEEDICIDES WAREHOUSES:

These facilities will stock 6 month supplies of all drugs that are needed for the various farms/crops/livestocks.

Databases will be established with user’s name, crops/livestocks and expected demand/quantities of drugs.

(C) FERTILIZER WAREHOUSES:

A 6 month supplies will be maintained, Databases established.

(D) PLANTS AND SEEDS NURSERIES:

A three month supplies will be maintained and databases established.

Only tested quality seeds/plants will be sold through these units to farmers.

Plants will be produced from the best materials available both locally and overseas.

Contracts to supply farmers with all their needs will be developed.

(E) EXTENSION SERVICES:

These units will be staffed by trained persons for field operations.

1) (a) Officers will visit homesteads and commercial farms to advice on good crops and livestock husbandry.

(b) Recommendations will be made by these officers.

(c) Samples of soils, leaves, tissues and water, any signs of infestations or diseases will be taken for further testing at the laboratories.

2) Special spray gangs for pesticide and weedicide applications will visit all farms and homesteads based on recommendations from the field inspectors.

3) Fertilizer application gangs will always be available.

4) Veterinary officers will visit livestock farms on regular basis.

Field officers will visit crop farms during husbandry, the pre-harvest, harvest and post harvesting periods.

5) These officers will advise on best practices, including timing of harvesting and transportation of produces to the Parks.

5.

6) Planting gangs will be available to sow all seeds and plants from the nurseries into the fields.

7) Harvesting gangs will be deployed to fields to harvest as per best practices.

8) Abbator gangs (of animals) can move into pastures upon orders.

(F) LIVESTOCK FEED SILOS AND DRUGS CENTRES:

These centres will retail livestock feeds from the Parks’ feed factories and imported drugs for the crop/livestock industry.

(G) MACHINERY POOLS:

These pools will have machineries and equipments such as tractors, excavators/drain diggers, bulldozers, draglines etc. to be rented to all farmers as needs arise.

They will be operated by trained staff from the pools.

(H) BREEDING CENTRES:

These centres will be temporary spaces where younglings from overseas are acclimatized, then passed on to the farms that placed orders.

They can also function as middle spaces where some farmers with surplus younglings, sell to the centres which in turn resell to other farmers at minimal markups.

(I) TRANSPORT TRUCKS:

These trucks (canters) will be fitted with cooling systems depending on the type of produces they carry, for example, vegetables from farms would need trucks differently outfitted from those transporting most fruits and meat products.

These trucks will travel to farms and buy the produces from individual farmers and take them directly to the parks.

They will also transport products from the parks to local retail outlets and to the export points for the overseas markets.

(J) PRE-COOL STORAGES:

Here produces are temporary stored at temperatures that are conducive for a longer shelf-life or compactness.

(K) MECHANIZED HANDLING FACILITIES:

Here produces are sorted, graded, washed, waxed/ ripening where necessary. Meat, fish, and shrimp products are appropriately dealt with.

(L) REFRIGERATING SETS:

These sets can be 20” or 40” containers with appropriate refrigerating units or/and concrete structures with cold storage systems in place.

In these sets are stored produces for the local or overseas markets, produces waiting to get in adequate quantities to start the processing or canning aspects at the factory levels.

(M) CANNING, PROCESSING AND CONCENTRATE FACTORIES:

When adequate supplies of farm produces are available based on seasonal outputs, these factories will start operations to add value to these produces whether as concentrates, processed items, canned or bottled products.

At these factories, emphasis will be placed on final products that have immediate markets rather than having surplus stocks in warehouses. For example, there may not be an immediate or adequate demand for tamarind, soursop or carrot drinks but a blend of these three produces as mixed juices may have a demand on the local and overseas markets.

(N) PACKAGING, LABELLING AND PALLETISATION FACILITIES:

These are the more important and strategic facilities. The whole process from the farms to the palates of the consumers can be enhanced here through the best packaging practices available, attractive labels and handy palletization.

(O) MANUFACTURED AND PROCESSED WAREHOUSES:

Finished Products can be stored here to a maximum of the shortest possible periods.

From here they should be disposed to the various local outlets and to the overseas markets.

(P) GENERATOR AND PUMP ROOMS:

These rooms will be under the control of the administrative buildings to control the proper functioning of the entire Parks.

(1) OVERSEAS MARKETS:

Clustered parks are more viable to manage exports to regional and international markets.

(2) FINANCE FOR FURTHER DEVELOPMENTS:

Local; regional and international financial institutions are more accessible through the parks.

(3) AGRICULTURAL LANDS:

There is availability of arable lands for further agricultural expansions both on the coastal strip and the riverside/interior locations. In many locations, drainage and irrigation systems can be further developed within short periods with minimum cost.

(4) THE FARMERS:

The large percentage of subsistence farmers can be valuable human resource to large scale agricultural ventures.

(5) AGRICULTURAL DEPARTMENTS AND INSTITUTIONS:

There are many institutions that have direct links to agriculture which are manned by qualified staff that the parks can rely upon.

(1) Ministry of Agriculture

(2) National Drainage and Irrigation Authority

(3) International Agriculture Organizations.

(4) Faculty of Agriculture

(5) School of Agriculture

(6) Agriculture Research Institutes.

(7) Departments of Lands and Surveys.

Farmers should be organized into four categories for all training and services:

(1) HOMESTEADS: Yard-space; growing vegetables and spices for EXPORT AGRO PARKS.

(2) MICRO: Growing crops (below 5 acres) worked and serviced by family members to sell produces to EXPORT AGRO PARKS.

(3) SMALL: Farmers with 5 to 25 acres of crops/livestock to sell to EXPORT AGRO PARKS.

(4) MEDIUM: Farmers having between 25 to 100 acres of cultivating lands concentrating on one or two crops/livestock to sell to EXPORT AGRO PARKS.

(5) LARGE: Farmers having over 100 acres of land producing specialized crops on contract to the Export Agro Parks.

A research project has shown that training 25,000 farmers in clusters (categories as above) around the EXPORT AGRO PARKS within a time period of 12-18 months is a viable option.

(a) Each Park will have defined boundary that encompasses enough lands and farmers for production.

(b) The management of each park will consist of:

1) Local (part) team of trustees

2) Local (part) Board of Directors

3) Local (part) upper management

4) Local middle management

5) Local workers’ Representatives

(c) Development of each park will be done by local contractors as far as possible.

(d) Local farmers will give orders and purchase all their needs: pesticides, weedicides, fertilizers, plants, seeds and all livestock etc. from the Park.

(e) All farmers will use the services and workers provided by the Park’s Extension Services.

(f) Farmers will use the Park’s trucks to transport their harvested crops to the Mechanized Handling Facilities of the park. Here the crops will be sorted, graded, washed and stabilized.

(g) The Research, Veterinary and Quality Control Station Services will be available to all farmers.

(h) The Administrative Building will be the centre of activity for each park.

(i) The Business Services Centre to cater for all the business services needs of the Shareholders at reduced costs and to other farmers and residents.

There will also be a building where small offices will be rented to large farmers.

(j) All Parks, as corporate bodies will have their annual general meetings, elect their Boards of Directors, their Trustees, and deliver their annual reports along with their financial statements.

(k) Local and overseas residents of each Park’s geographic location will have an emotional attachment and will consider the successes of their Parks as their extended successes and would contribute to their further developments and successes.

(l) Each Park will provide 7 days, year round employment for local residents.

From farms to the palates of the consumers, the farmers are the key factors, but they are poorly equipped to act their roles and are not in control of the major processes of agricultural production yet they are is expected to compete on the world market with:

(a) Competitive prices

(b) High Quality produces

(c) Adequate Quantities of produces

(d) Reliable supplies

1) The Guyanese farmers need to move into commercial farming on a scientific basis.

2) They need to know their costs of production and how they can reduce them to make profits or bigger profits.

3) They need to know about quality planting materials, rich soils, good pre-harvesting, harvesting and post-harvesting methods, add values to their produces while meeting world market requirements.

4) The farmers are not in control of most of the stages in the process of agricultural production. Middle-men who have no relationship with the agricultural sector supply some of the major inputs such as fertilizers/drugs at high mark-ups while other middlemen purchase their produces at low prices.

5) Farmers will respond to changes if shown that they can make bigger profits.

6) The farmers need to be trained about these aspects.

THESE PARKS CAN FULLY AID THE FARMERS TO COMMERCIALIZE THE AGRICULTURAL BUSINESSES IN THE FOLLOWING WAYS:

(a) The training of the farmers in the cost of productions and the value of their produces. The nature of soil compositions and their adjustment and relationship with production. The value of good planting materials, good husbandry, harvesting methods, and value added methods and proper marketing in line with world market standards.

(b) The centralization of their business processes where they can receive management advises from the parks administrative offices, gets all business services done and some have small offices of their own.

(c) All their researches, veterinary and quality controls will be done by the parks.

(d) The parks will purchase fertilizers, weedicides and pesticides etc. direct from overseas suppliers. These being major inputs for the agricultural sector they can greatly reduce production costs. The farmers can always access direct, at reduced prices and reliable supplies all their agri-inputs.

(e) Other major inputs in the process are quality planting materials, seeds and live-stocks which the Parks can adequately supply after local and overseas sourcing. The feed silo and drug centres will supply the live-stock industry.

(f) The extension services can be the other key inputs:

1) Skilled workers in all aspects of field work will take off the farmers’ headaches with employees.

2) They will have all the equipment and machineries (from the pools) to do all types of field jobs. They can clear the land, plough, develop drainage and irrigation systems, sow the seeds and planting materials, spray, apply fertilizers and harvest crops at economical labour costs to the farmers, while giving quality services because of their scientific trainings. Because of the existence of the extension services, the farmers will further reduce production costs by not having to purchase large amount of equipment and machineries which they use only for short periods.

3) The Parks will contract large machineries such as Bull-dozers, Excavators etc. to do land preparation for farmers.

4) By purchasing inputs and services from the parks, the farmers, through the parks can calculate the value of their crops and seek insurance coverage.

(g) The Parks purchasing of farmers’ produces at more or less guaranteed prices would add security to the farmers, not having to buy transportation vehicles, face crop spoilages, no markets or low prices.

(h) The Parks would be in a better position to handle repairs to equipment, machineries, trucks, through their workshops while providing pre-cooling, sorting, grading, washing, waxing, ripening and refrigerating services.

(i) By establishing the concentrate, processing and canning factories along with the packaging, labeling and palletization centres, these Parks will value-added these farm produces thus making these parks and agri-farms more competitive and profitable in the best interest of the farmers.

(j) The selling of fertilizers, weedicides and pesticides to the sugar and rice industries while processing some of their products, rice and sugar, will be added greatly to the Park’s profitability because of the volumes and can thereby lead to increase benefits to farmers.

(k) When properly organized through these Export-Agro parks with adequate insurance coverage, Financial Institutions will be eager to do business with farmers, thus completing the whole process of commercial agriculture.

(l) With the establishment of rice factories and abattoirs at most Parks, feed factories become more feasible. These feed factories can use up all residues on the farms; vegetables, fruits, provisions, poultry products, fish, rice mills and abattoirs by-products to make rich feeds at economic cost since most ingredients will be free. Low priced feeds will drop the production cost in lot of areas in agriculture.

These Parks will identify be foreign sources of materials and equipments. As well as finding markets (foreign) for produces and value added products.

(A) BUSINESS SERVICE CENTRES:

These centres will make a small profit markup on all their services to farmers/customers.

(B) FARMERS’ OFFICES:

Offices at each park will be rented to large farmers. These offices will assist large farmers to better organize themselves into economic/financial units.

(C) RESEARCH, VETERINARY AND QUALITY CONTROL SERVICES

These centres will charge a small commission on all contracted farmers for services provided.

(D) PESTICIDES, WEEDICIDES, FERTILIZERS, LIVESTOCK FEEDS AND DRUG STORES.

These centres will provide all the needs of farmers in the parks’ geographic areas. These centres will buy their supplies directly from the manufacturers/vendors and will supply to farmers at prices that can further reduce production costs.

(E) EXTENSION SERVICES AND MACHINERY POOLS:

These services/pools will provide labour, small/large equipment for all field operations.

These centres will serve these parks and farms as mini Employment Bureaus. Small profit markups will add to the further profitability of parks.

(F) BREEDING CENTRES:

1) Cattle

2) Sheep

3) Pigs

4) Goat

5) Alligators

6) Ducks

7) Bees

8) Turkeys

9) Tilapias

10) Pacus

11) Hassars

12) Shrimps

13) Prawns

(G) HEAVY EQUIPMENT AND MACHINERIES:

1) TRANSPORT TRUCKS:

These trucks will minimize transportation costs of produces from farms to parks. They will be economically viable since farms will be supplying the parks on a daily basis.

2) RERIGERATING SETS:

These sets will stabilize farm produces and store large quantities for the low harvesting seasons.

3) CANNING, PROCESSING AND CONCENTRATE FACTORIES:

These factories will be the major centres where value added will take place. They will be the places where the largest profits will be generated.

4) PACKAGING AND LABELLING:

Further values will take place at these centres making the products more marketable.

5) GENERATORS AND PUMPS:

These units will protect the assets in the parks from flooding and electricity shortages.

6) RICE, ABBATTOIRS AND FEED FACTORIES:

These operations will enhance the profitability at the parks by utilizing most by products from the farms.

(H) PACKAGED PRODUCES AND PRODUCTS:

Final produces and products from the handling facilities/ factories will carry a small profit margin to make these more competitive thus making the parks more profitable.

(1) Farmers’ Training Centre in the different segments of the sector.

(2) Plant Nurseries should be adequately developed/ stocked to satisfy all plants needs of farmers and should be the base from which farmers will be recruited and trained to develop commercial agricultural enterprises.

(3) Administrative Centres can assist farmers to better organize themselves competitively e.g. obtaining banking and insurance services; penetrate foreign markets (with distributing centres).

(4) Office Spaces for large farmers.

(5) Business Centres to satisfy office needs of others.

(6) Research, Veterinary and Quality Control Services for farmers’ technical needs.

(7) Pesticides, Weedicides, Fertilizers, Livestock Feeds and Drug stores negating middlemen.

(8) Livestock Breeding Centres to supply farmers’ needs.

(9) Machinery Pools for general land preparations and servicing.

(10) Extension Services with trained workers to do land preparations sowing/planting, crops husbandry, harvesting and preparations for marketing/distribution/processing centres.

(11) Rental of vehicles to transport produces from farms to markets/processing centres.

(12) Mechanized Handling Facilities for sorting, grading, washing, waxing, ripening etc.

(13) Pre-cooling and Cold Storage Facilities to stabilize and preserve produces.

(14) Abattoirs, Rice Mills, Feed Factories to service live stocks and incorporate farm residues.

(15) Processing/ Concentrate/ Canning Factories as value added entities for all farm produces.

(16) Packaging, Labeling and Palletization services for all products passing through park.

(17) Warehouse Spaces for all fresh and manufactured products.

Generator Room

These Stations will be under the control of the administrative complexes to control the proper functioning of entire Parks. +Read More

PROCESSED PRODUCTS WAREHOUSES

Finished Products can be stored here to a maximum of the shortest possible periods. +Read More

PUMP ROOM

These Stations will be under the control of the administrative complexes to control the proper functioning of entire Parks. +Read More

PACKAGING, LABELING & PALLETIZATION CENTRES

The whole process from the farms to the palates of the consumers can be enhanced here through the best packaging practices available, attractive labels and handy Palletization. +Read More

ADMINISTRATIVE COMPLEX

Provide administrative Services to entire 500 acres park +Read More

BUSINESS CENTRE

Our Business Centre Office +Read More

OFFICES FOR LARGE FARMERS

Our Office for large Farmers. +Read More

RESEARCH DEVELOPMENT

Administrative serves to farmers +Read More

PESTICIDES WEEDICIDES

Pesticide and Weedicide Services for Farmers +Read More

LIVESTOCK FEED SILOS

These centres serves to factories and imported drugs for the livestock industry +Read More

FERTILIZERS

We provide fresh fruits without any pesticides. +Read More

CANNING PLANTS

When adequate supplies of farm produces are available based on seasonal outputs. +Read More

PROCESSING PLANTS

These factories will start operations to add value to these produces whether as concentrates, processed items, canned or bottled products. +Read More

CONCENTRATE FACTORIES

These factories will start operations to add value to these produces whether as concentrates, processed items, canned or bottled products. +Read More

PLANTS & SEED NURSERY

Plants will be produced from the best materials available both locally and overseas. +Read More

EXTENSION SERVICES

Extension Services for Farmers. +Read More

MACHINERY POOL

They will be operated by trained staff from the pools. Centralized repair/servicing workshops will be part of the pools. +Read More

FEED FACTORY

FEED FACTORY +Read More

RICE MILL

RICE MILL +Read More

ABATTOIR

Abattoir +Read More

REFRIGERATING ROOMS

These sets can be 20” or 40” containers with appropriate refrigerating units or/and concrete structures with cold storage systems in place. +Read More

MECHANIZED HANDLING FACILITIES

Here produces are sorted, graded, washed, waxed/ ripening where necessary. Meat, fish, and shrimp products are appropriately dealt with. +Read More

PRE COOL STORAGE FACILITIES

Here produces are sorted, graded, washed, waxed/ ripening where necessary. Meat, fish, and shrimp products are appropriately dealt with. +Read More

SPECIALIZED TRANSPORT TRUCKS

Here produces are sorted, graded, washed, waxed/ ripening where necessary. Meat, fish, and shrimp products are appropriately dealt with. +Read More

MECHANIC WORKSHOP

Mechanic Workshop +Read More

BREEDING PIG

Mating purebred individuals of the same breed. +Read More

BREEDING GOAT

Natural service is the easiest and most common breeding system for goats. +Read More

BREEDING RABBIT

Rabbits have a high reproductive rate compared to other livestock. +Read More

BREEDING DUCK

Ducks can be raised for both meat and egg production. +Read More

BREEDING TURKEY

The turkey breeding industry is very labour intensive +Read More

BREEDING CATTLE

At a minimum, production, fertility and health traits are involved. +Read More

BREEDING HONEY BEES

Honeybees can have a lethal gene which can cause spotty brood patterns. +Read More

CHICKEN HATCHERY

Chickens can produce fertilized eggs year-round, but they tend to be more prolific during the springtime. +Read More

BREEDING ALLIGATOR

Most alligator mating takes place in May and June, with nesting in late June and July. +Read More

SHRIMP AND PRAWN

Shrimp and prawn are types of seafood that are consumed worldwide. +Read More

TILAPIA PACUS & HASSARS

Tilapia is tolerant of a variety of aquaculture environments; it can be farmed in brackish or salt water and also in pond or cage systems +Read More

CROPS AND LIVESTOCK PROCESSING

API/AQUCULTURE PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

POULTRY PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

VEGETABLES PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

SPICE PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

FRUITS PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

PROVITION PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

RUMINANT PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More

LIVE STOCK PROCESSING

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s +Read More